Smaller Manufacturers Competing with Giants via Intelligent Lifting Automation Technologies

In today's fast-paced business environment, every minute counts. For small and medium-sized enterprises (SMEs), smart lifting automation has emerged as a necessity rather than a luxury. By automating repetitive and heavy lifting tasks, SMEs can significantly improve productivity, enhance worker safety, optimise limited space, and scale operations efficiently.

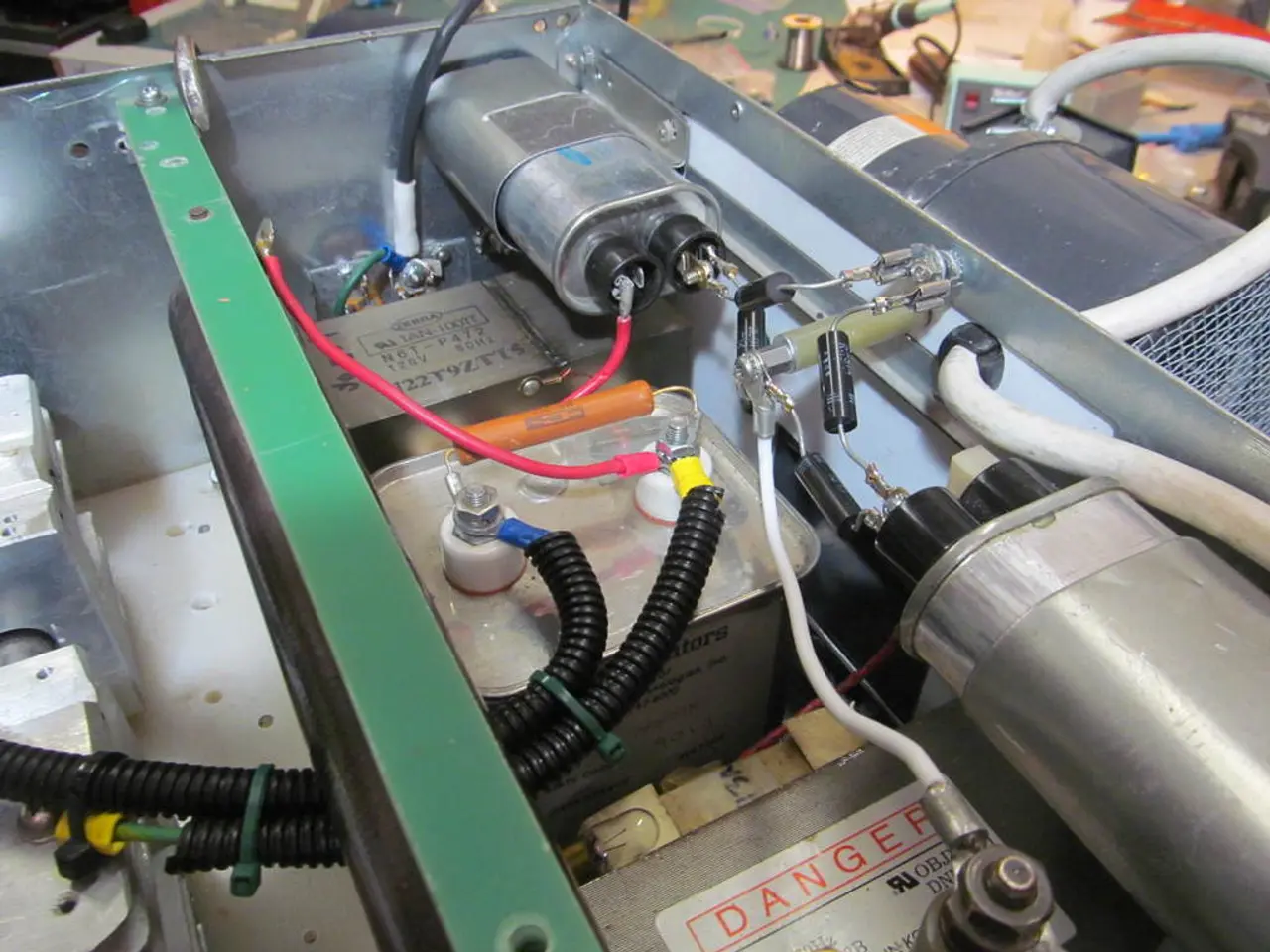

Manual or motorized cranes can be chosen based on the volume of work, while wall or pillar-mounted cranes can be selected according to the manufacturing layout. Smart lifting solutions, such as Loadmate's space-saving cranes and hoists, can help small manufacturers achieve big wins. These solutions can be as simple and affordable as Wall Mounted JIB Cranes, Pillar Mounted JIB Cranes, or Electric Chain Hoists.

Lifting a 300 kg load manually can take significant time, manpower, and increase the chance of injury. Repeated manual lifting can affect performance and delay delivery timelines, potentially damaging a business's credibility. Smart lifting solutions can minimize worker fatigue and OSHA violations by reducing manual lifting, creating a safer work environment.

Smart lifting automation, often realised through collaborative robots (cobots), offers numerous benefits. For instance, cobots can increase SME productivity by 15% to 50%. They handle tasks such as welding, assembly, and machine tending, resulting in shorter lead times and higher throughput. In logistics, cobots speed up order picking and packing, doubling operational speed during peak seasons.

Cobots also reduce workplace injuries by taking over strenuous and injury-prone lifting and material handling tasks. They minimize worker fatigue and repetitive strain, lowering risks associated with heavy manual lifting and repetitive motions. Unlike traditional industrial robots that require large safety cages, cobots have a compact footprint and are designed to operate safely in close proximity to human workers, making it easier for SMEs with limited physical space to integrate automation within existing workflows without costly facility redesign or expansion.

Smart lifting automation enables SMEs to scale operations flexibly and cost-effectively. Automated systems can handle fluctuating demand by extending working hours without additional labor costs, and facilitate rapid changes in production lines or fulfillment processes. Faster return on investment (often within 6-18 months) allows SMEs to reinvest gains into growth initiatives. Automation also frees workers for multitasking and quality assurance, improving overall operational agility.

Visiting the website can help explore compact, custom-built lifting solutions. Maker's Row connects small and growing manufacturers with vetted suppliers, automation specialists, and industrial partners across the USA, streamlining the process of upgrading equipment or sourcing parts locally.

In an era where every minute counts, smart lifting is not a luxury but a necessity. By embracing smart lifting automation, SMEs can boost productivity, enhance worker safety, optimise limited space, and scale efficiently, driving competitiveness and sustainable growth in increasingly dynamic markets.

- In the fast-paced business world, small-business owners can leverage the finance sector to invest in smart lifting solutions, such as collaborative robots (cobots), from the technology industry, which can boost productivity by 15% to 50% in the manufacturing industry.

- By integrating smart lifting automation, small manufacturers can optimize their workspace and reduce the risk of workplace injuries, thereby avoiding OSHA violations and preserving their business reputation.

- For small and medium-sized enterprises, partnering with companies like Maker's Row can provide access to custom-built, compact lifting solutions, helping them to scale operations efficiently and maintain a competitive edge in dynamic markets.