The Benefits and Influence of an Assembly Line are a Manifestation of Efficient Production Methods.

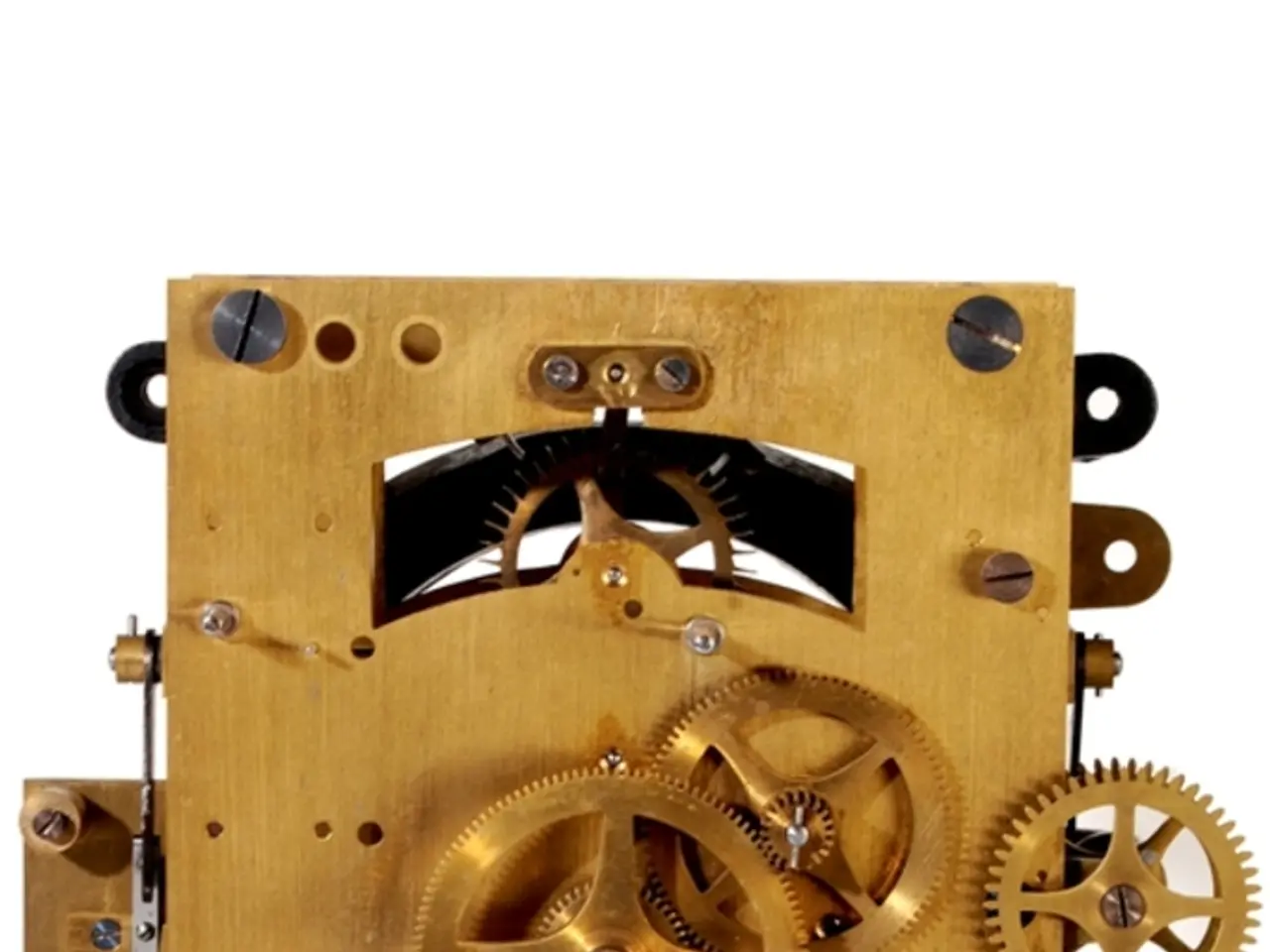

In 1913, Henry Ford introduced the moving assembly line to the world, revolutionising the manufacturing industry and reshaping industrial processes globally. This groundbreaking innovation drastically reduced production time and costs, paving the way for mass production at unprecedented scales.

Ford's assembly line cut the assembly time of the Model T from over 12 hours to just 93 minutes. This rapid production speed made products more affordable for the middle class, a shift that was unprecedented at the time [1][2]. This innovation, often referred to as "Fordism," had a profound impact on the manufacturing sector, rapidly spreading beyond the automotive industry to sectors such as electronics, appliances, textiles, and consumer goods manufacturing [1].

The assembly line improved efficiency, reduced costs, and allowed for scalability, making it the preferred manufacturing approach across diverse industries [1]. Ford's innovation also laid the foundation for later innovations in manufacturing, such as automation, quality control systems, and just-in-time production pioneered by Japanese manufacturers like Toyota. These developments further enhanced efficiency, quality, and cost-effectiveness in global manufacturing [1].

Moreover, Ford's model shifted the industry's focus from luxury to affordable, practical products. The Model T became the world's first truly mass-produced and widely accessible automobile, accounting for nearly 57% of global auto production by 1921 [2][4].

Each worker on an assembly line specialises in a specific task, minimising time wasted on switching between tasks and reducing overall production time [3]. Assembly lines also facilitate the use of automation and machinery, reducing reliance on human labour and decreasing operational costs [4].

Quality control on assembly lines minimises the chances of faulty products reaching the market, enhancing customer satisfaction [5]. Assembly lines ensure high-quality products through standardised production processes and quality control measures at each stage [6]. Furthermore, assembly lines implement standardised procedures and training programs, ensuring consistent quality across all products [7].

In conclusion, Henry Ford's assembly line profoundly impacted global manufacturing by introducing rapid, cost-efficient mass production techniques that shaped modern industrial economies and consumer markets worldwide [1][2][4][5]. This innovation continues to influence manufacturing practices today, underscoring its enduring significance in the modern world.

References: [1] "The Moving Assembly Line: A Revolution in Manufacturing." History.com, A&E Television Networks, 2021, www.history.com/news/the-moving-assembly-line-a-revolution-in-manufacturing. [2] "Henry Ford and the Model T." Ford Motor Company, Ford Motor Company, 2021, www.ford.com/about-ford/our-company/history/henry-ford-and-the-model-t. [3] "Division of Labor in Manufacturing." Investopedia, Investopedia, 2021, www.investopedia.com/terms/d/division_of_labor.asp. [4] "The Impact of Henry Ford's Assembly Line on the Automobile Industry." ThoughtCo, ThoughtCo, 2021, www.thoughtco.com/impact-of-henry-fords-assembly-line-on-the-automobile-industry-1415020. [5] "Quality Control in Manufacturing." Quality Magazine, Quality, 2021, www.qualitymag.com/articles/93359-quality-control-in-manufacturing. [6] "Standardization in Manufacturing." Manufacturing.net, Manufacturing.net, 2021, www.manufacturing.net/articles/2014/1/standardization-in-manufacturing.aspx. [7] "Training in Manufacturing." Manufacturing.net, Manufacturing.net, 2021, www.manufacturing.net/articles/2014/1/training-in-manufacturing.aspx.

- The innovation of the assembly line, first introduced by Henry Ford in 1913, was not only limited to the automotive industry but also significantly influenced other sectors such as finance, technology, and electronics due to its impact on efficiency, cost reduction, and scalability.

- The drastic decrease in production time enabled by the assembly line stirred a shift in focus from luxury to affordable, practical products in various industries, including finance, technology, and consumer goods manufacturing, making them more accessible to a wider audience.